I never understand my motives. I always buy things cause they are cheep but when I get started using them I get mad because I buy junk, I would say china junk , but right nowadays most 3d printers are coming from there.

We have a never break policy to buy only American, did I mention this costs 2 hundred bucks, I'm a sucker. Policy well I guess I'm a hypocrite, I'm so glad china doesn't make General Aviation Planes or helicopters cause I'd surely be in the ground, after you get going and realize these machines really are not complicated. We replace the electronic controllers right out of the box to duet wifi. Most other hardware just needs adjusting and tuning to keep running.

If your a beginner you will soon find most of the advise you get off screwtube is useless promoting and selling.

There are basics you need to understand and if your like me you have to experience them first hand to learn.

Update feb 2023:

At this point I have 6 lk1 printers working printing lots of stuff but mainly I have been developing a 3d printed drone body. I can't even explain how much stuff has been printed. I have made some upgrades, direct feed extruders the best, also PEI sheets for the heated beds. Here is a video link to some parts getting made

The printer in the background at the end is O'Red, my very first, still kicking out parts 24/7

This was before I converted all my machines to Duet WiFi controllers. I'll leave the links in case someone needs the files

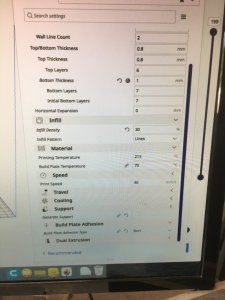

Did a firmware update today. they have a marlin version, the update went smooth working a print now to see if I am still in service These are the latest firmware from newest (marlin) first

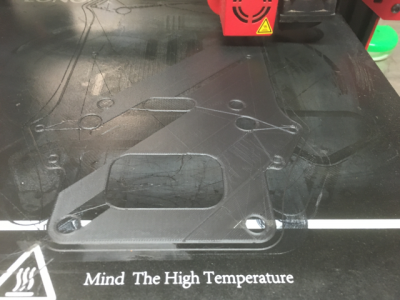

Started a new drone project

required carbon fiber reinforced filament

The prints are very large, right to the max dimension of this printer but yes I am glade i have the capability

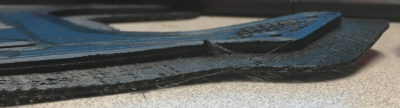

So it starts out with a good print of the lower body then i started getting a shift in the print

couple prints later and things went haywire. to make things short Through my troubleshooting I found a set screw in the framework channel. The issue being in the x axis my inspection reveled the set screw missing on the pulley and of course the pulley was slipping. Post print from reinserting the set screw