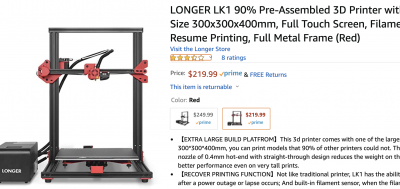

I never understand my motives. I always buy things cause they are cheep but when I get started using them I get mad because I buy junk, I would say china junk , but right nowadays most 3d printers are coming from there.

We have a never break policy to buy only American, did I mention this costs 2 hundred bucks, I'm a sucker. Policy well I guess I'm a hypocrite, I'm so glad china doesn't make General Aviation Planes or helicopters cause I'd surely be in the ground, after you get going and realize these machines really are not complicated. We replace the electronic controllers right out of the box to duet wifi. Most other hardware just needs adjusting and tuning to keep running.

If your a beginner you will soon find most of the advise you get off screwtube is useless promoting and selling.

There are basics you need to understand and if your like me you have to experience them first hand to learn.

Update feb 2023:

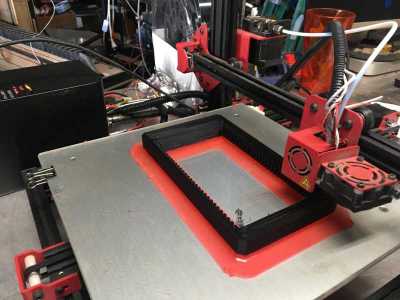

At this point I have 6 lk1 printers working printing lots of stuff but mainly I have been developing a 3d printed drone body. I can't even explain how much stuff has been printed. I have made some upgrades, direct feed extruders the best, also PEI sheets for the heated beds. Here is a video link to some parts getting made

The printer in the background at the end is O'Red, my very first, still kicking out parts 24/7

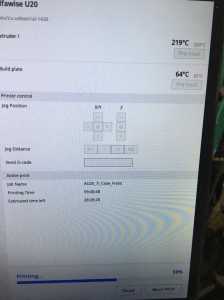

The printer had been making parts at a great pace then It started getting an error on the display. what was happening was the head temp would not get hotter than 180, it just stuck

Heat Temp not exceeding 180 degree

I could reset the machine but it would error during prints.

My first attempt was to update to marlin 2.o but still error

I then changed the hot end but then realized the temp probe had almost fallen out. The screw was stripped in the aluminum block, this screw holds the probe inside the hot end block.

Either way I replaced both the heat element and temp probe.

Wires pushed directly through the case to the mainboard not wired through the connectors.

The heat element and temp sensor purchase was 12 bucks for 5each so it was quick and inexpensive`.

My current prints are back to a good solid quality

Pay attention in the beginning and make adjustments based on what you see and the strength of the part

This picture illustrates the start print on the left until the final one on the right. Conditions on the beginning of the print caused lifting and deformation. Reducing the bed heat until the final result is acceptable. the print stays on the plate and the print is dimensionally correct

as you can see on the fourth try it's almost there but some separation is evident. 1 strand. There are other conditions that can be causing this and adjustments will be mage and results posted.

Ok big update: It's 1 year in service and this unit finally put me to the task. It Broke and it was a hard troubleshooting.

condition: error with head heater

The unit just wouldn't print right, the head kept clogging and things were not right.

I replaced the head with a unit that had the heat break, changed the tubing and still just didn't print right

Finally after watching the control panel heat the end then the bed it became apparent the bed was taking the heat cycles and not letting the nozzle maintain the 220 temp.

There is a trouble shooting video for the bed resistance and this checked out good. Turns out the mainboard just wasn't up to the task any longer. Fortunately I had a removed board from a system duet2 upgrade , after installing it's BACK UP! started a print job and it's into it 35 hours, 55%, so far so good.

For the purposes of the cheap large scale printer I wanted to stay as close to stock as possible so to continue the production and learning using a off the shelf unit with OEM parts