When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

Holy Moly i have met the Big Challenge. Ok so it's supposed to be an affordable build, under 1000 dollars. It uses a Simple control board so it specs. But I have a brand new unopened ultimachine archim so lets give it a try. It took a day to remember how to use Arduino IDE and to remember how it compiles a file then it doesn't with the same file. Then I tried visual studio route and made some progress but ended up back to the Arduino setup. Here is where I ran into problems

(helpful tip) setup a separate laptop that can communicate with the control board, when you get a good build put it in the laptop so when you get lost without hope you can plug it in and get the board back up)

The build instructions for the high-temp 3d printer provides the operating system for the controller but It's Repietier. 1/2 day later and 15 downloads and the board never displayed any lcd or any signs of life.

Right now I am running the software provided by the wiki Archim site Marlin4Due

I am running Pronterface and the machine acts like it should except for the 1500 setting that are in the Repieter File than I need to somehow change in the Marlin file.

End-stops are configured and the machine centers like a core X,Y machine so I am somewhat satisified.

Next is setting up the heated bed and nozzle heating elements

Still weeks away from a first print. This machine has a rotating table for the nozzle and allows for standard heated nozzle with Borden tube feeder. I might try that first or not

Part of doing this build was to get a better understanding of the extruder and how it operates. I posted a pretty detailed post on the extruder and nozzle options, I think this is going to be a hugh improvement for 3d printing going forward, that is on an industrial scale

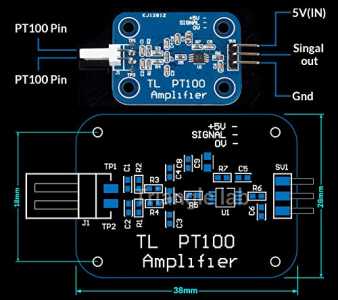

Time to setup the heating being this is a high temp build there is gonna be high voltage and very hot elements. Installed is a dedicated 24v power supply feeding two power expansion modules. the two modules are connected to 1 main board heater output and 1 thermal temp reader. The intent is just heat the block as one unit. There is a pt100 amplifier and probe but jot setup yet. I just used a basic thermal probe to get the computer sending the heat-up signal and record some temp. Worked great, heat elements getting red hot real fast and displaying temp.

The heated bed was a different story, getting a great deal on a high-temp e3d bed (20 bucks) I realized it was 220 volts, Now that's another exploration into electrical wonderland. UK 220 is single wire and us is 2 wire and they don't just join together.

I was lucky (I

hope) and got a deal on amazon for a 110 up-converter to 220 @ 500 watts for 20 bucks so if it works I still did ok on the bead but that isn't getting heated today. While I wait for the pieces I will finish cutting the box panels and spend more brain cells on the rapitier-marlin conversion.

I purchased another screw setup and will build a second modified and updated extruder using the experience from the first and the research from the extruder posts on the forum

Second attempt at getting the print head mounted. This is ver2 in the plans for the rotory head. The first broke at the mount and attempts to fiberglass it failed. There just is not enough material on the base to support the nozzle weight

maybe I'm obsessed with getting this extruder stiff, I put an angle bracket on and it stiffened it right up.

Right now I am just interested in getting some plastic flowing through the nozzle and working on the software setup. I will consider the bed leveling probe and other hot end after. I need to get this oven tightened up, sealed up, heated up and pushing out some plastic.

still the major hurdle is the belt. ordered yesterday, got ripped off from mcmaster, they make you purchase the item then after they screw you with shipping. at this point if the belt works it will be worth it. The belt being the biggest bullcrap missing peace from the plans. a simple size or part referance would have been nice.

Right now after a couple months building this jewel I am starting to think it's a bad design and I was mistaken to undertake the build. 1000 dollars maybe, 1000hrs to build defiantly

++++The belt arrived and it worked +++++++ The golden ticket #962T80 1/4'' Mcmaster-carr

Getting the pellet intake aligned and bore cleaned out to get this box closed in and the pellet funnel installed. I ordered some plain pellets off e-bay for 18 bucks. There are lots of instructions on heating the pellets in the oven to dry them out before use. I still have the pt100 amplifier to hook up. requires marlin adjustment but I am getting ready to put a .stl to this thing, maybe a 5 day countdown

Disregard this info: Setting up repietier on rambo&archim total disaster and major waist of brain activity. I now believe the marlin and aurdrino setup is a disaster, and i mention windows also, a trio of conflicts and errors. The build will be shored up and the oven completed this week, the control board and pt100 daughter board in the mail. Duet 2 wifi and repieter

I was able to identify an analog input on the archum controi board. After 5 hours into the night and 4 hours this morning trying to get arduino IDE or visual studio to compile a marlin file I gave up. I ordered a DUET 2 WIFI control board. This decision was based on the provided firmware for the project is Repietier build and it would not configure for the archim, in fact i couldn't get a build for another ultimachine rambo to work either. The archim has a version of marlin on their wiki page that works and configures for core xy so the machine is operating and if i can get the pt100 board to talk to it i will be moving forward, It's just the acknowledgment that even though the arcmin board is 32 bit it is old and unsupported, my thoughts are ardruino for shops will be replaced with Duet systems. Did I mention I purchased a real Duet not a clone. The build continues, closing up the oven in progress