When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

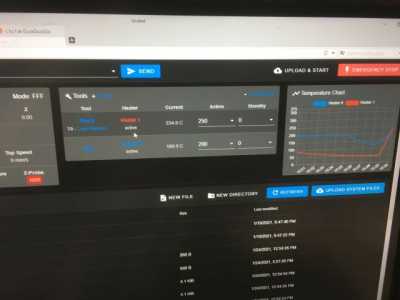

Tuning the heat systems and learning how to adjust the Duet Main board

Now the current task is to get the screw extractor pushing out melted plastic.

currently the heat sinks are joined at the bottom. The plastic pellets I have appear to large and

my attempts to reduce their size have failed.

There is a scientific paper posted in PDF form on this build forum that covers heat zones and what happens to plastic in the nozzle

There is not a lot of information on the searches I have done on this system, my searches using duckduckgo of course

Taking temp readings in (f) It appears the bowl gets pretty hot, I have the heads separated and the space in between is consistent with the heat blocks. The heat elements are 70 watts and should do 400c, yes I have started a fire not paying attention and an element came out and torched the box. There are several warnings with the software to not leave the unit unattended.

The bowl appears to be hot enough to melt the pellets but it also has a fan duct with air moving over the radial fins. My analysis is the screw needs to turn counter clockwise to push the plastic out and my guess at a pretty slow rate. I would say this is the weak point in the system but so far this complete build appears to be Not Worthy of the effort.

I will figure out the screw extractor, there is an alternative hot end setup that uses the standard method but that defeats the purpose of building this, the idea is to be able to use recycled materials and exotic stuff that is not available in a spool.

Getting close to melted plastic coming from the extruder head. Minor setback

I always thought the inserts in the manifold were a weak design. Primarily because the extruder needs to be disassembled a lot. at least during this trial and ERROR period. gonna do a through bolt system. the bottom plate can be perminate but the upper is attached to the motor.

yes it's a crude world. anyway I bent some metal to incorperate the base and sides so I could through bolt the manifold. Not trying to make a beauty queen just doing some rough prototyping. If this nozzle is like anything else on this project it will be a few days befor the thing screws plastic out of a .4 tip

I am having trouble controlling the upper heat element. the duet doesn't sent the heat up command to the heater so i have it running off the lower one, they are supposed to track but they dont, I figure I need the control because the upper is melting the plastic in the hopper. My next idea is to lower the upper heat down with the lower one, allowing the pellets to not be melted at the inlet. Also there is a recommendation to dry the pellets for several hours before using, maybe this is adding to the issue with the pellets not moving into the hopper. I watched the build video of another screw extractor and noticed that the the inlet of the barrel has cuts in it to help with the pellets moving into the screw

this is the inlet of another build