When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

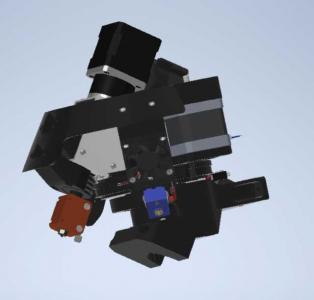

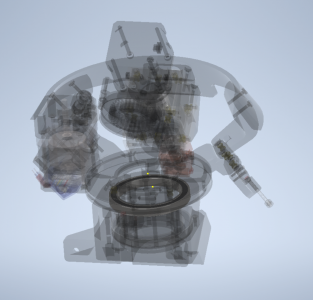

Spent some time understanding the print head. The plans have a couple versions

The Rotary tool head is what we are building. It has a pellet screw assembly and also a e3d head assembly

It looks pretty complex but after looking at the inventor model it all came together

There are 2 seperate head assembles, one has a screw for pellets and the other a bowden extruder

This is the screw setup, it has a geared motor and a coupler

https://robotdigg.com/product/1604/3D-Printing-pellet-extruder-screw-and-barrel

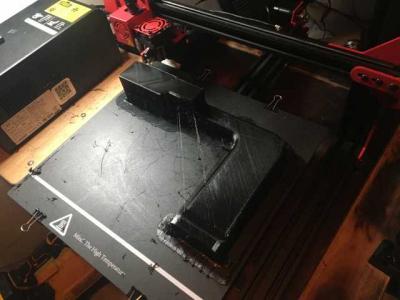

I will detail the parts for the head build, the printing continues and today i started setting up

a plasma cutting table to cut the metal parts.

I was concerned about building this print head setup because I didn't understand the objective of having a

bowden and extruder also but it's a interesting configuration

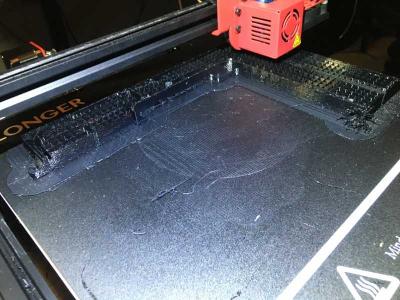

Just finished the largest part. Fan duct. it took 37hrs. I had 2 false starts, one was an issue with the filiment breaking, I changed to brand new roll, second was the mesh type. I think i changed to cross mesh. either way am glad to have this out of the way

Today the metal frame arrived, last night i ordered all the required parts to build the rotating head.

I cut some aluminum parts today with my plasma table, I think I am having diamention issues, the software i have seetup is pretty basic, I installed a basic plasma controller on my plasma table just to get it functioning. The original controller was dated and had dated proprietary software. anyway the cuts look smaller than the plans.

I have a mpcnc router table built, might try to use that for better accuracy

Getting it dialed in