When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

Wasted the day trying t get a post processor setup in fusion360 or inventor. I hate auto-desk, why they just cant have simple help files is amazing to me. Did i mention i fucken hate auto-desk!

no way to open the bullshit cad files and go to cut with uccnc, wasted day, why cant there be a cad program that works with uccnc or a riprap boards. always the crap freecad and extra difficult linux flavors. It's no wonder why most men dont want to mess with cnc, so much non standard bullshit. DXF my ass , just because it's a common file type doesn't mean it will open or run

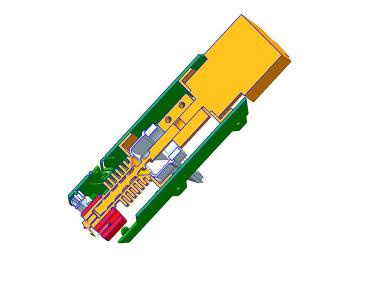

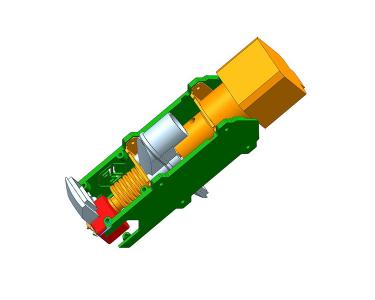

These are extruder is from china, different from the one being built here but interesting

open in a new tab and zoom in you can see the screw and barrel

I have posted the process to get images from apple iphone to the forum. Using a windows pc is the way to go, having to deal with apples crap iphoto and their stupid management process is just plain dumb.

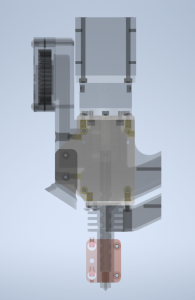

here is the screw and barrel for the pellet extruder. It says to run duel heaters, I am looking for alternative options