When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

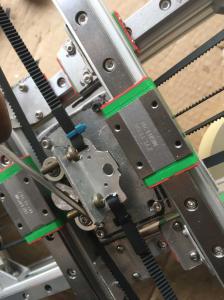

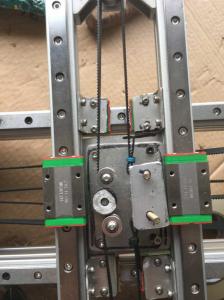

belt pulley build

looking at the picture i notice i have the drive pulley backwards. i would say the driven pulley goes to the x axis but i dont know yet which axis is which, the driven pulley on the transmission faces the motors and this is backwards live and learn, sure the machine would have acted special if i missed this

fixed

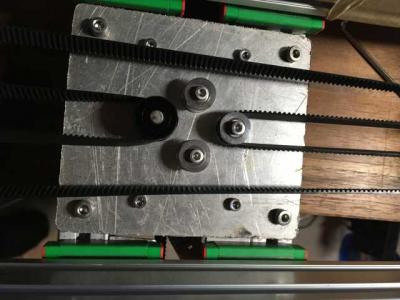

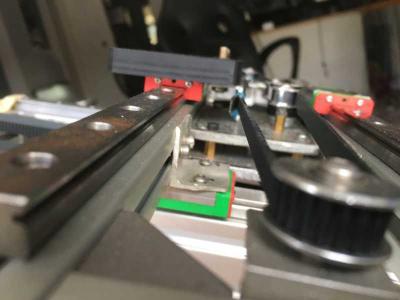

got back to attaching the base plate. This is the solution for the belt attaching and plat attaching I cam up with

Got around to picking up the ball bearings and packing the bearing carts