When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

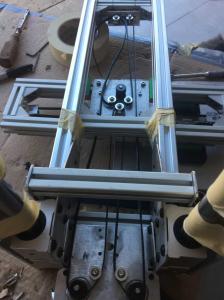

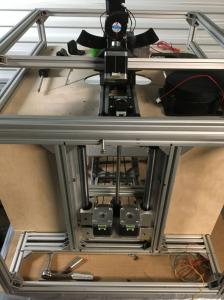

Working on the x,y belt system. connecting the belt together with a printed coupler. added a tension system for tightening

In all the blue prints and cad models the belt routing didn't incorporate the 2 pulleys next to the driven wheel. I almost didn't install these 2 wheels cause I didn't think they were used, But when routing the belt the belt doesn't engage the driven pulley unless you route around these 2 pulleys . in order to get the belt teeth engaged with the 3 driven gears. 2 on the motors and center 1

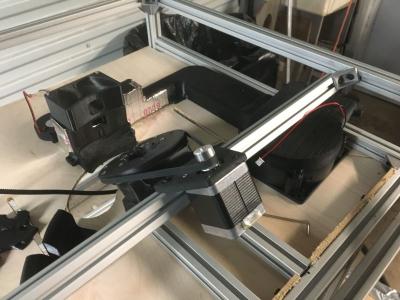

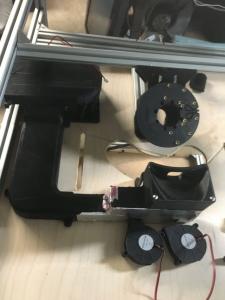

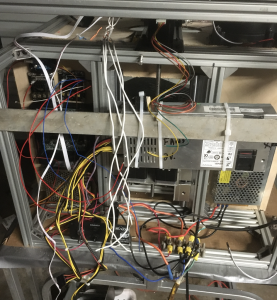

Setting up the Print head was difficult. This is an area to mod, the head is heavy and bulky. The mount breaking just trying to screw it down. I actually used fiberglass on the mount, but will install a metal bracket in the next build. The inserts are also set to close. I think the next rotating assembly will screw through, other options will be considered as the other mounts for the probe and other hot end as the build continues. just trying to get this setup solid for now so i can get the motors wired and moving