When I get this operational I will put together a build manual with high rez images. If you want more details or better images just ask. In this build process I am making changes to help in quicker builds. I am building separate components for spares and for mods. I am approaching this build as individual modules that can be removed and replaced quickly

These pictures are from the original builder and their process:

https://www.sciencedirect.com/science/article/pii/S2468067220300390

https://www.fabbaloo.com/blog/2020/9/28/open-source-high-temperature-reprap-3d-printer-announced

Today I start identifying the parts and start looking for materials. No China Build is the strategy

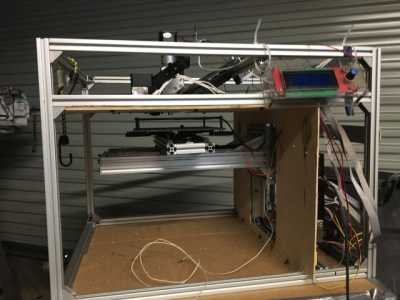

IT'S ALIVE

Getting back to reality I started with editing marlin 2.0. This build is using ulitmachine archim 1.

The best part of that decision was I had the board as a spare and also because it's not a POS china board it worked right out of the box. It had earily marlin and there is a 2.0 available so the task of programming that is at hand.

Things that need to be identified is the home position. The current home is out and right so that's where i will put the end stops and also configure the belts so they can reach the parameter of the hot bed.

This is the hot end at xyz home Next we have the belt run and pullies. The plan was to move the belt splice at the end of the outboard run hoping to have enough travel to reach the other extreme, this I dont know yet

I encountered a problem with the pully levels. With the table at the extreme the pullies all get real close, problem is the y carrier pullies are not at the same level and the belts are not straight.

Looks like the quick fix is to re drill the angle bracket so the pullies can go in farther, this pulley setup has the jam nut configuration, the right setup would be countersunk screws on the back so the bracket can be flush without any obstruction or potential of hitting the transmission bracket

much better

I established a proper Core X,Y operation with marlin. Still alot of code adjustments left but I figured

I would do some operations and see how the mechanical s operated. Also started messing with limit switches. The system defect currently is the belt. The build pages don't list a belt size and It's becoming oblivious the 1 piece belt is required. I tried several methods to connect the belt ends, my final attempt was superglue and aircraft safty wire. problem is the joint wont go around the pullies. I have it setup I believe now with the belt connection at it's farthest point and the table in home position. This should all continued testing while i wait for a belt. My sizing on the belt is 37.75 in (959mm) 6mm wide GT2 (edit: belt purchased was 976mm 488 teeth. This belt received was half the required length so measuring a printer belt is twice the stretched length. will try a 1900 mm belt next)

I am trying to locate a close size and will make adjustments to the system to get it tightened

Belt attempt #2 part # mcmaster -carr

| Belt Trade Number | 962MXL025 |

The design plans and all pictures available show the belt drive going directly to the x axis drive gear and not going around the 2 pullies, they show the pullies just installed, not used. The problem is the belt needs to enguage the drive pully with the belt teeth and not the flat side. I was able to get a 1 piece belt ordered, a detailed inspection of the belt routing will be done then, the current objective is to get the machine running a build cycle and moving in all directions to find the issues and build errors.

X,Y theory has offically given me a headache. this is Home, X0,Y0. I have explored moving table core x,y systems and have gotten no examples so this is how I am setting up until I learn otherwise

looking from the front (actually side) this has a door and lcd panel

X axis the lower and Y axis the upper