Slicing

Here are some important parameters which are control while slicing.

- Wall Thickness

- Layer Height

- Layer Width

- Nozzle and Bed Temperature

- Retraction

- Line Width

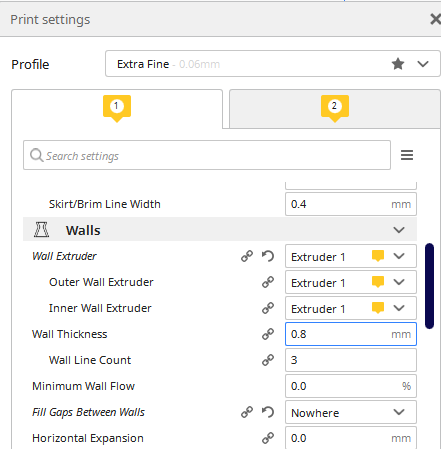

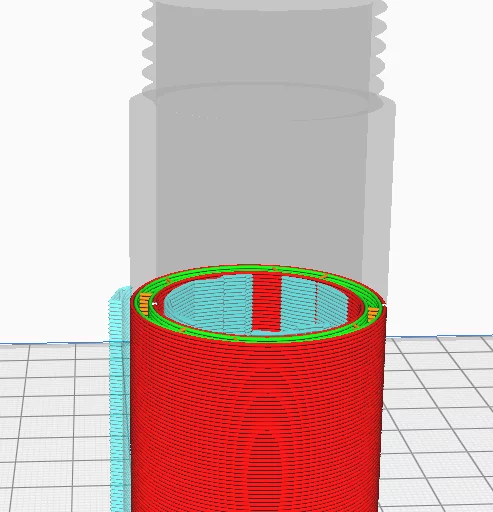

Wall Thickness

Assigning correct wall thickness is helps you to reduce the material uses and print time. Wall thickness may differ for each different material.

You can also control the quality of your print by selecting print order of wall, In print order, you can select which wall has to be print first internal or outer.

300w" data-sizes="(max-width: 441px) 100vw, 441px" data-was-processed="true" />

300w" data-sizes="(max-width: 441px) 100vw, 441px" data-was-processed="true" />Layer Height

It describes how much height each layer has. In high detail print, you need to decrease the layer height so you can achieve a smooth surface finish but it increase the print time.

On the other hand in low detail print, you need to increase layer height so your surface finish may decrease but minimize the print time.

Nozzle and Bed Temperature

In case you need high-speed extrusion of material so you need to increase the nozzle temperature thus material gets melted in less time.

Also after unpacking filaments if you store them without any protection from the air, they absorb moisture, in that case, their melting point may increase due to the presence of moisture.

Also, you need to change the heatbed temperature according to your material so the material will stick well with the heatbed and decrease the chance of wrapping.

There are many other methods also to decrease the chance of wrapping.

Retraction

In a custom build printer, you have two options for extruder type (1)Direct Drive Extrude (2)Bowden Extruder.

In a direct drive extruder, you need to set retraction distance less than 1mm and in a Bowden type extruder, you need to set retraction distance less than 4mm.

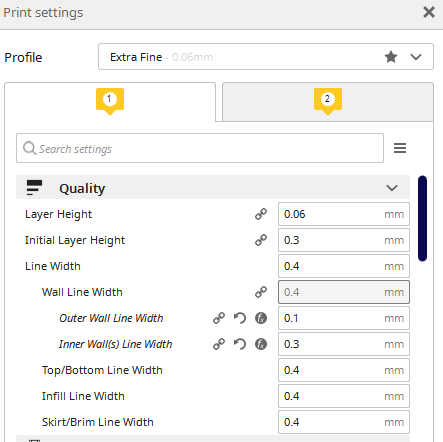

Line Width

In layer width, you can control the width of a single printed line. In 3d model, there are many different types of lines.

If set correct line width for each type of line it may result in good quality print and less print time. Here are some line type:-

- Top and Botton line width

- Infill line width

- Skirt and Brim line width

- Support line width

- Initial line width etc.

Something to keep in mind

There are many other advanced parameters to play with it. If you want to be more productive in 3d printing learn about them. Learn them also because your final print(Quality, Structural Strength, Print Time, and Cost of Print) heavily depend on them.

FAQ

There is mainly 5 types of line widths in 3d printing i.e. top & bottom, infill, skirt & brim, support line, and initial line width.

There are six types of parameters to control while slicing some important of them are wall thickness, layer height, and layer width.

150w,

150w,